Edge Computing in Industrial Automation: Boosting Efficiency and Safety

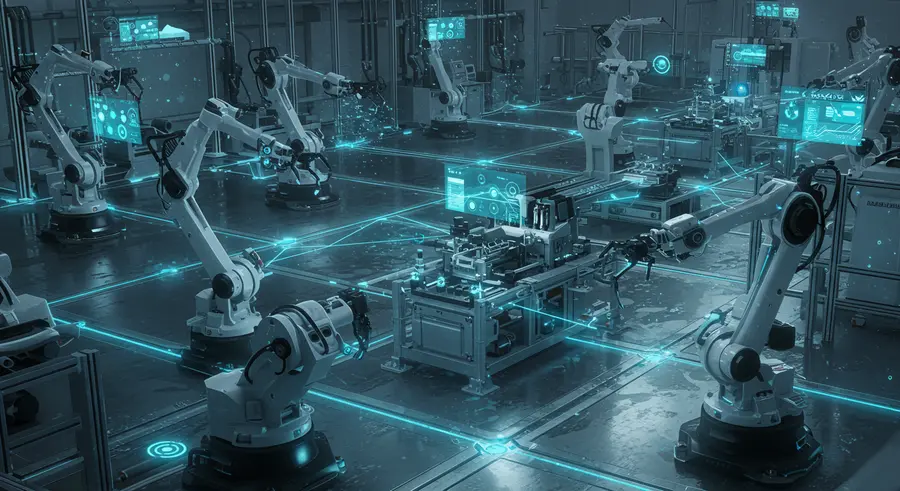

Industrial automation has been a cornerstone of modern manufacturing for decades, driving efficiency and precision. However, as the complexity of operations grows and the demand for real-time insights intensifies, traditional centralized cloud architectures often fall short. This is where edge computing steps in, bringing computation and data storage closer to the operational technology (OT) devices on the factory floor.

The Rise of Edge in Industry 4.0

Industry 4.0, characterized by the convergence of IT and OT, relies heavily on interconnected systems, sensors, and intelligent machines. Edge computing provides the necessary infrastructure to handle the massive volumes of data generated by these devices, enabling immediate analysis and response. By processing data at the edge, industries can reduce latency, minimize network bandwidth consumption, and enhance data security.

Key Benefits of Edge Computing in Industrial Automation:

- Real-time Decision Making: Critical applications like robotic control, quality inspection, and predictive maintenance require instantaneous responses. Edge computing allows for data processing within milliseconds, crucial for preventing machinery failure or ensuring product quality.

- Enhanced Operational Efficiency: By optimizing data flow and enabling localized analytics, edge solutions can identify bottlenecks, streamline processes, and reduce downtime, leading to significant cost savings.

- Improved Data Security and Privacy: Sensitive operational data can be processed and stored locally, reducing the risk of cyber threats associated with transmitting data to the cloud. This is particularly vital in critical infrastructure and highly regulated industries.

- Reduced Bandwidth Costs: Instead of sending all raw data to the cloud, only aggregated or analyzed insights are transmitted, significantly lowering bandwidth requirements and associated costs.

- Offline Operation Capability: Edge devices can operate autonomously even when connectivity to the central cloud is interrupted, ensuring continuous operations and resilience.

Applications Across Industries

Edge computing's impact is visible across various industrial sectors:

- Manufacturing: Predictive maintenance of machinery, real-time quality control, robot coordination, and supply chain optimization.

- Energy: Smart grid management, remote monitoring of oil and gas pipelines, and optimizing renewable energy generation.

- Logistics and Transportation: Fleet management, real-time tracking of goods, and autonomous vehicle operations in warehouses.

- Mining: Autonomous heavy equipment, environmental monitoring, and safety systems.

Challenges and Considerations

While the benefits are compelling, implementing edge computing in industrial environments comes with challenges, including managing distributed infrastructure, ensuring interoperability between diverse devices, and addressing cybersecurity concerns for edge devices. However, ongoing advancements in hardware and software are continually addressing these hurdles.

The Future of Industrial Automation is at the Edge

As industries continue their digital transformation journey, edge computing will play an increasingly pivotal role. Its ability to provide immediate insights, enhance operational resilience, and secure critical data makes it indispensable for the factories, power plants, and logistics networks of tomorrow. The convergence of AI and edge computing will further unlock capabilities, creating truly intelligent and autonomous industrial systems. For comprehensive market insights and to analyze financial trends in the evolving industrial landscape, explore how advanced tools can provide an edge in your financial research.